Seal Bag Packaging Machine: High-Performance Packaging Solution

When paired with the Seal Bag Packaging Machine, this system offers a seamless, integrated solution for packaging. The combination of the precise weighing capabilities and the secure sealing function ensures that your products are accurately measured and professionally packaged, providing the highest quality and efficiency for both food and non-food applications.

This integration allows for smooth workflow automation, where the products are not only weighed with utmost precision but also sealed in bags with a high level of security, maintaining freshness and extending shelf life. Furthermore, the Seal Bag Packaging Machine contributes to significant time savings, labor reduction, and improved operational consistency, making it an indispensable tool for businesses looking to optimize their packaging processes and enhance the overall presentation and performance of their products.

Whether you're packaging food items like snacks, candy, or frozen foods, or non-food items like hardware and plastic components, this powerful combination ensures your packaging meets industry standards while boosting productivity and reliability.

Key Features and Benefits

Elegant 4-Side Seal Design

The machine creates quad-seal bags with a 3-dimensional structure that enhances the bag’s appearance. This design ensures the packaging looks more premium and high-end, ideal for products that require a professional finish.

Advanced Control System of Seal Bag Packaging Machine

Featuring an imported PLC computer control system, this machine integrates a user-friendly interface with a large, high-precision color touch screen. The intuitive controls make operation smooth and efficient, even for first-time users.

Precision Film Handling

The servo-driven double-belt film pulling system ensures accurate positioning and maintains consistent bag sizes without deviations. This guarantees stability and reliability, reducing waste and saving time.

Intelligent Emergency Response

With its self-diagnostic emergency stop function, the machine minimizes downtime and protects your operations from unnecessary losses, enhancing overall efficiency.

All-in-One Packaging Solution

This machine combines multiple processes, including bagging, filling, sealing, printing, punching, and automatic counting. Its automatic correction function ensures precision at every step, reducing errors and improving productivity.

Temperature Stability

Utilizing an independent PID control system, the sealing temperature is maintained with a minimal deviation of ±1°C, ensuring strong and consistent seals for various materials.

Applications

The Seal Bag Packaging Machines showcase remarkable versatility, making them an essential solution for a variety of packaging needs across multiple industries. Their advanced design and functionality allow them to efficiently handle a diverse range of products, including snacks, coffee, tea, pharmaceuticals, pet food, granules, and powders. This breadth of capability ensures that businesses can rely on a single machine to meet the packaging demands of different product categories, significantly reducing operational complexities and costs.

For the food and beverage sector, these machines excel at preserving freshness and extending shelf life by creating airtight seals for products such as chips, ground coffee, loose-leaf tea, and other perishable items. In the pharmaceutical industry, they ensure precision and hygiene, packaging pills, capsules, and powders in tamper-proof pouches that comply with stringent regulatory standards. The pet food industry benefits from their ability to accommodate bulk packaging sizes, catering to both individual servings and large resealable bags.

One of the standout features of these machines is their adaptability. They can easily be configured to produce customizable packaging sizes, offering businesses the flexibility to cater to evolving market demands and consumer preferences. Whether it’s small sachets for trial products or larger bags for bulk purchases, these machines can handle it all. Furthermore, their high-speed production capabilities ensure that businesses can maintain efficient workflows and meet tight deadlines without compromising on quality.

This combination of versatility, adaptability, and efficiency positions the Seal Bag Packaging Machines as a cornerstone for industries striving to enhance their packaging processes and deliver superior products to the market.

Why Choose Our Machine?

Our Seal Bag Packaging Machine is designed with modern businesses in mind. It boosts efficiency, supports multifunctional packaging needs, and ensures precision and reliability. With a focus on automation and ease of use, this machine reduces labor costs and accelerates production, making it a smart investment for your business growth.

Whether you’re packaging delicate powders or durable granules, this machine delivers exceptional performance with minimal effort. Choose the Seal Bag Packaging Machine to elevate your packaging process today!

Packaging & Delivery

-

Packaging Details

-

Our packaging process is designed with meticulous attention to detail to ensure the machine is delivered in pristine condition, ready for immediate use. Here's a comprehensive breakdown of the steps we follow to guarantee the safety and integrity of the equipment during transit:

Dedusting and Cleaning:

Every part of the machine undergoes a meticulous cleaning process to remove dust, debris, or residue. This ensures the equipment remains hygienic and free of contaminants, preserving its quality and performance.

Lubrication of Drive Parts:

To protect moving components during transportation, we apply high-quality lubricants to all drive parts. This step prevents corrosion, reduces friction, and ensures that the machinery operates smoothly upon installation.

Modular Disassembly:

For safe handling and efficient packing, the machine is carefully divided into individual modules. Each module is systematically categorized and labeled, making reassembly straightforward and hassle-free at the destination.

Plastic Film Wrapping:

Each module is securely wrapped in durable plastic film to protect against moisture, dust, and minor scratches. This extra layer of protection ensures that the machine remains in optimal condition throughout the journey.

Wooden Case Packing:

The wrapped modules are then placed into custom-made wooden cases, which provide robust protection against physical impacts, vibrations, and other external stresses during shipping. These cases are engineered to handle the rigors of long-distance transportation, offering maximum durability.

-

Port

- GuangZhou,ShenZhen,FoShan

-

Lead Time:

-

| Quantity(Sets) |

1 - 1 |

2 - 5 |

>5 |

| Est. Time(days) |

15 |

20 |

To be negotiated |

fully speed 1kg 2kg 3kg 4kg 5kg vacuum sealer machine packaging automatic

What are the Applications of Seal Bag Packaging Machine?

Application

01. Product application:

The SUNCHON fully automatic multi-head weigher packaging machine, combined with a Packaging Sealing Machine for Bags, offers a comprehensive solution for efficient and precise packaging across various industries. It is designed to handle a wide range of materials, including grain, sheet, strip, and irregularly shaped items. From candy, melon seeds, chips, peanuts, nuts, and preserved fruits to jellies, biscuits, confectionery, camphor balls, currants, almonds, chocolates, filberts, corn, potato crisps, and puffed snacks, this machine excels in ensuring consistent weight and high-quality packaging.

Additionally, the Seal Bag Packaging Machine enhances the overall process by providing secure and professional sealing for products, making it ideal for pet food, dilatant snacks, hardware, and plastic components. Together, these machines streamline operations, improve efficiency, and ensure precise rationing while delivering durable and visually appealing packaging that meets diverse product needs.

What description of our Seal Bag Packaging Machine?

Product Description

02. Product feature: Seal Bag Packaging Machine

The SUNCHON fully automatic multi-head weigher packaging machine, when paired with the Automatic Seal Bag Machine, provides an enhanced and fully integrated solution for efficient and intelligent packaging operations.

Efficient: This system streamlines the entire process, combining bag-making, filling, sealing, cutting, heating, and printing date/lot numbers in a single step, significantly reducing production time and increasing throughput.

Intelligent: With a user-friendly touchscreen interface, the packing speed and bag length can be easily set without the need for part changes, ensuring flexible and adaptable operation for a wide range of products.

Professional: The independent temperature controller with heat balance functionality allows for the use of different packaging materials, ensuring optimal sealing and product preservation regardless of material type.

Characteristic: The automatic stop function enhances safety by halting operation if an issue arises, while also saving film and reducing material waste during the packaging process.

Convenient: Designed for ease of use, the system offers low operational costs, saves labor, and simplifies maintenance, making it a practical choice for businesses of all sizes.

Weighing Accuracy: The multi-head weigher offers precise weighing accuracy, with a range from 0.2 to 1.0 gram, ensuring consistency and quality control for every packaged item.

03. Machine Specification: Seal Bag Packaging Machine

(We have several models. We can customize the suitable one for you according to your requiredment.Just Tell us : Weight or Bag.)

| Modal |

SUN-320W |

SUN420W |

SUN520W |

SUN720W |

| Measuring range |

150-800ml |

150-1500ml |

150-2000ml |

150-4000ml |

| Packaging speed |

5-70bags/min |

5-60bags/min |

10-60bags/min |

10-60bags/min |

| Bag width |

50-150mm |

60-200ml |

80-250mm |

100-350mm |

| Bag length |

80-240mm |

80-300mm |

80-350mm |

100-450mm |

| Film roll width |

Max.320mm |

Max.420mm |

Max.520mm |

Max.720mm |

| Film thickness |

0.03-0.09mm |

| Film material |

OPP/CPP PET/PE PET-AL/PE lamination film,aluminum film |

| Machine size(LxWxH) |

1185*935*1245mm

|

1217*1015*1343mm

|

1488*1080*1490mm

|

1716*1260*1820mm

|

| Machine weight |

350kg |

450kg |

550kg |

700kg |

What is Seal Bag Packaging Machine?

The Seal Bag Packaging Machine is engineered to pack products with quad seal bags. The quad seal bags also known as block bottom bags or flat bottom bags, have four panels on the sides that give them a boxy shape when filled. These bags are popular in the food and snack industry, as they provide a stable and attractive packaging solution for a variety of products.

What are the Features of the Seal Bag Packaging Machine?

The Seal Bag Packaging Machine and the Quad Bag Packing Machine are both innovative packaging solutions that not only offer precision and efficiency but also elevate the visual appeal of your products.

The Quad Bag Packing Machine features a 4-sided seal quad design that enhances the packaging's three-dimensional, captivating allure. This unique design ensures that the products stay secure while exuding a high-end, visually appealing charm, making them stand out on store shelves.

Equipped with an imported PLC full computer control system, the Quad Bag Packing Machine provides a user-friendly man-machine interface and a high-precision, large color touch screen for ease of operation. Additionally, its imported servo double-belt film pulling system ensures impeccable accuracy in positioning, guaranteeing that each package is perfectly aligned.

This machine offers all-in-one efficiency, capable of integrating bagging, filling, sealing, printing, punching, and automatic counting into a seamless process. It also includes an automatic correction function, ensuring perfection in every bag.

In a competitive market where presentation and performance are paramount, both the Bag Sealing Packaging Machine and the Quad Bag Packing Machine stand out as the ultimate choices. They marry elegance and functionality seamlessly, ensuring that your products not only stand out but also meet the highest standards of precision and reliability.

How Do I Choose A Quad Bag Packing Machine?

You may think choosing a quad bag packing machine is a complex task, involving several factors such as product type and size, production capacity, the machine’s flexibility and versatility, package quality and consistency, as well as machine maintenance and durability.

In reality, consulting with Suntech, a leading manufacturer of quad bag packing machines, simplifies the process. Suntech offers a wide range of quad bag packing machines tailored to meet diverse packaging needs, ensuring you find the perfect solution that aligns with your specific requirements. Whether you're looking for high precision, reliability, or seamless integration with your production line, Suntech’s expertise in designing and manufacturing these machines guarantees an optimal fit for your business.

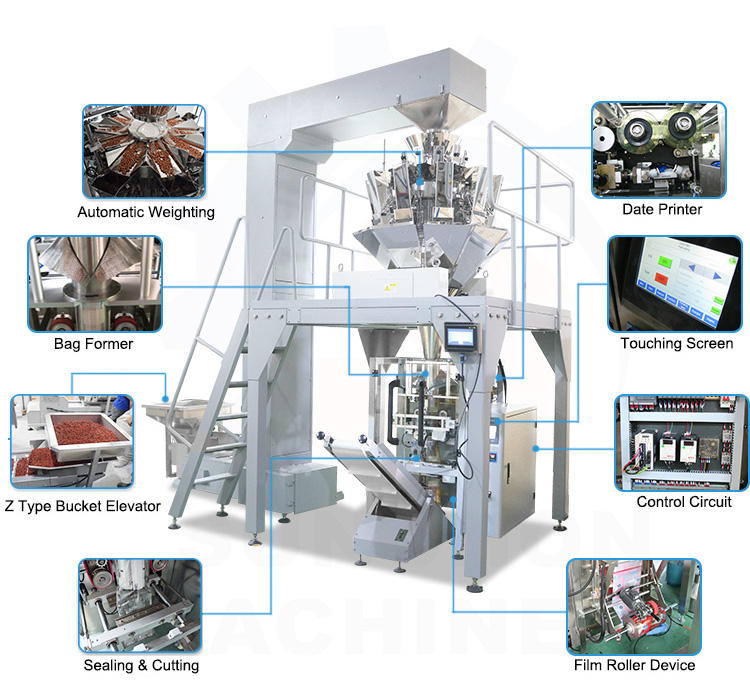

04. Product detailed: Seal Bag Packaging Machine

|

Name: Seal Bag Packaging Machine

a) 4 heads, 10 heads, and 14 heads can be optional.

b) Weigher buckets have independent control mode. When compared to the standard weigher, speed is increased by 10%, enabling faster and more accurate calculations.

c) The counting function can satisfy diversified weighing requirements.

d) The sample collection function enhances the accuracy of the weighing process.

e) New features include low supply warning, controllable feeding, automatic material filling, and failure rejection functions.

f) It is suitable for weighing granules, slices, rolls, or irregularly shaped materials such as candy, seeds, jelly, fries, coffee granules, peanuts, puffed foods, biscuits, chocolates, nuts, chips, pet food, frozen foods, and more. It is also ideal for weighing small hardware and plastic components.

When paired with the Seal Bag Packaging Machine, this system offers a seamless, integrated solution for packaging. The combination of the precise weighing capabilities and the secure sealing function ensures that your products are accurately measured and professionally packaged, providing the highest quality and efficiency for both food and non-food applications.

|

Name: Main Packing Machine

precision bag former & touch screen, digital screen display with numerical setting and flexible operation; Imported PLC control system and color touching screen, easy operation; PID independent control of temperature, more suitable for different packaging material.

|

|

|

Name: Z Type Elevator (Optional)

a) The elevator and electronic metering scale is used together, control circuit is used to control material's position,realizing automatic feeding and stopping function.

b) The elevator can be made of stainless steel or carbon steel, according to the customer, choice.

c) The Bucket conveyor (Z-shaped) is designed to handle both tough and sanitary applications.

d) They are available in a range of sizes and materials and well-suited for granular and slice products, for example: chips, frozen food, pet food, cookies, nuts, small hardware, recycling, building and metallurgical industries etc.

|

Name: Finished Product Conveyor (Optional)

Adopting imported miniature motor and featured with low noise and long tifetime. It can transport finished goods to platform, reduce waste during packing, making the machine work more smoothly.Greatly submitted production efficiency and reduced labor costs.

|

|