Looking through the world, you can find that almost all the products have a good package to ensure the something inside is secure. This may be one of the symbols of the rapid development of the economy. In this phenomenon, the auto packing machine makes a significant contribution. In this post, the author would introduce you to the auto packing machine.

What is Auto Packing Machine?

An automatic packing machine is a crucial part to achieve the auto packing product process. The automatic packing machine is capable of packing the products without the need for manual human intervention. And, with the rapid development of online shopping and the eager market for packing, the auto packing machine has improved from a single machine automating one step in the packaging process to now integrating all steps seamlessly into the entire packaging process.

What are the Main Parts of an Auto packing Machine?

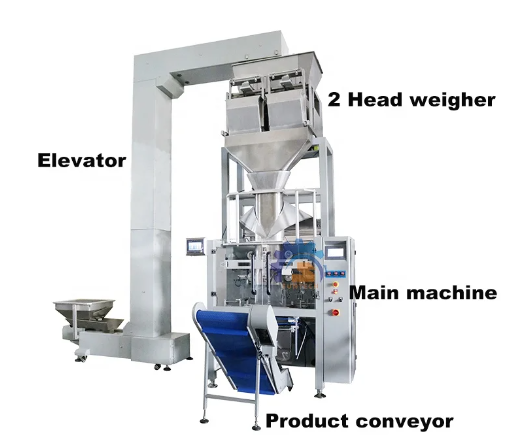

As a matter of fact, because of the various products to be packaged, packing machines are various in the market. In this section, the author will take the automatic powder packing machine as an example to illustrate the main parts of the packing machine.

●Multi Heads Weigher

This part is a fast, accurate, and reliable weighing machine and is used for weighing the items such as candy, jelly, coffee granules, small hardware, plastic component, etc.

●Main Packing Machine

This part consists of a precision bag former, a touch screen, and a digital screen display. The operators complete the packing setting in this machine. With the imported PLC control system and color-touching screen, the operators can finish the settings without too much effort.

●Z Type Elevator

The elevator is made of stainless steel or carbon steel. The Z-type elevator and electronic metering scale are used for togethering, and controlling the circuit which is the component to control the material’s position, realizing automatic feeding, and stopping function. The Z-type elevator is a good helper in packing the granular and slice products, such as chips, frozen food, pet food, cookies, nuts, etc.

●Finish Product Conveyor

The conveyor is used for transporting finished goods to the platform. It reduces waste during the packing process and improves the machine's working efficiency.

How Many Grams of Products Can the Machine Pack?

The packing ability of the auto packing machine depends on the type of packed products and the design of the machine. In the following part, the author will take the automatic vertical packing machine as an example to illustrate the packing ability of the auto packing machine. The normal automatic vertical packing machine can pack 10-1000g. And, the packing capability of the machine is determined by the model of the machine and the design of the machine.

|

Model |

SUN-420 |

SUN-520 |

SUN-720 |

|

Measuring Range |

10-1000g |

10-2000g |

100-5000g |

|

Packaging Speed |

5-60bags/min |

10-50bags/min |

10-40bags/min |

|

Bag Width |

60-200mm |

80-250mm |

100-350mm |

|

Bag Length |

80-300mm |

80-350mm |

100-450mm |

|

Max Film Roll Width |

420mm |

520mm |

720mm |

Benefits of Auto Packing Machine

The auto packing machine is the fruit of modern technologies, which bring multiple benefits to many companies.

●Productivity: In manual packing, it takes too much time to pack the boxes and other products. And the workers also tend to be tired from repetitive, monotonous, and strenuous packing activity, as a result the packing efficiency also relatively gets down. As for the auto packing machine, it can work longer at full efficiency. They also offer higher packing speeds.

●Low wastage: Since the auto packing machine is well-design, it can cut the material precisely and make full use of the packing material by using well-defined patterns. Furthermore, it simplifies the packaging process and reduces material waste.

●Employee Safety: When the workers pack the items in the warehouse, they usually have to take risk of forklift accidents, cuts, tears, and back injuries. When the automatic packing machine is introduced to your company, it could let the workers outside of the danger of forklift accidents, cuts, tears, and back injuries.

●Quality: The automatic packing machine allows the operators to set and standardize all the details about the packing, so they improve product quality, cycle time, and operations in general.

●Customer Confidence: The package of the item may be the first impression of the company. The package may present whether the company cares about its customers. The auto packing machine can make great packaging with accurate information. Then the good package may help the company promote the brand. For example, in the food industry, the automatic food packing machine can well pack the food, so it could let the customer learn the company very cares about food safety. Furthermore, the customer can keep the food for a much longer time.

●Great Product Protection: If you use the right auto packing machine and set the right packing setting, the product can be securely packaged. For example, a good auto packing machine can wrap your products well and let the products safe from contamination.

Conclusion

All in all, the automatic packaging machine is crucial equipment in many fields to ensure product safety and improve working efficiency. The high-quality and advanced automatic packing machine a guaranteed efficiency.

Suntech is a packing machine manufacturer, offering the most advanced technology in the automated packaging machine. Also, Suntech specializes in providing custom automatic food packing machine for all types of application.

.jpg)

.jpg)

.jpg)