For food product suppliers, a good package is essential. And, as the food industry continues to grow, the efficiency of the production line is also important. Then, how to make a good balance between a good package and efficiency is important.

Then, investing in food packaging equipment is a good solution. In this post, the author will give a basic discussion about the food packing machine.

What Are the Steps in Food Packaging?

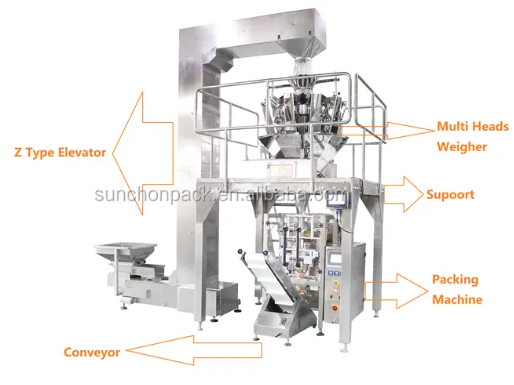

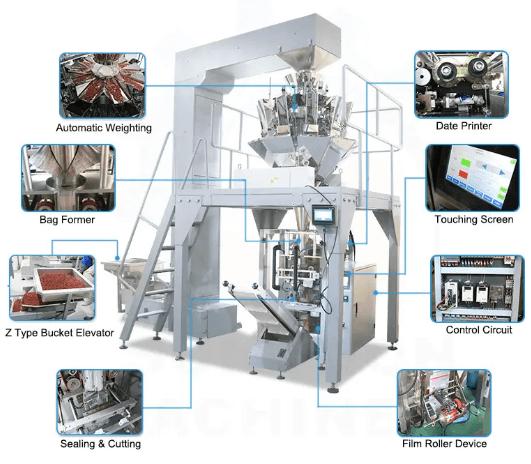

In Suntech’s automatic food packing machine, the whole process can be divided into 5 steps. The first step is dosing the granule food into the machine. Second, the food would conveyed into the distributing machine by the convey belt. Third, the food would be filled into the package. Fourth, when the filling is complete, the machine forms the bag to make a complete-sealing package. Fifth, the machine cut the continuous package.

Automated Food Packaging Systems

What Is the Production Capacity of Food Packing Machines?

The production capacity of food packing machines can vary significantly depending on several factors, including the type of machine, the complexity of the packaging process, and the specific food product being packed. Different machines are designed to handle various production volumes, ranging from small-scale operations to high-speed, large-scale production lines.

In Suntech, we have a wide range of food packaging equipment in various production capacities. The Sun-320 food packaging machine can pack 5-70 bags per minute. The SUN 420 food packaging machine can pack 5-60 bags per minute. The SUN-520 food packaging machine can pack 10-50 bags per minute. The SUN-720 can pack 10-40 bags per minute.

China Food Packing Machine

What Are the Advantages of Food Packing Machines?

The food packing machine is a good helper for the food industry. It not only can improve the package efficiency but also can avoid many potential risks in the packaging process. In this section, the author will list what benefits the food packing machines offer.

●Improve Food Safety

Food safety always is a priority in the food industry. The traditional labor packaging method is easy to leads to many food safety problems such as food pollution, bacteria accumulation, incomplete sealing, etc. When food packaging workers handle food products, there is always a risk of bacteria spreading from one product or area to another. Then, an automatic food packing machine can eliminate human contact throughout the process, significantly reducing the risk of contamination.

Also, supported by the advanced packaging system, the automatic food packing machine can make the complete sealing package, so it also can eliminate the danger of inadequate seals as well as contamination during storage or transportation.

●Reduce Downtime and Bottlenecks

The automatic food packing machine is powered by electricity and doesn’t need a break. By contrast, workers need a break after a long time working. If the workers don’t have enough breaks, the mistakes in the packaging process may increase. In other words, less time stop, more products packaged, leading to increased profits.

Additionally, while human error can lead to bottlenecks, food packaging equipment has fewer opportunities for errors, lowering the chances of bottlenecks.

●Make More Precise Measurements

Automated food packaging systems typically have built-in precise calculation systems, so they automatically calculate weights and volumes to package food products at exact measurements. Then, more accurate weight measurements are an effective way to reduce product waste, increase cost efficiency, and prevent selling underweight containers.

●Offer Flexibility and Versatility

When large orders come in or seasonal peaks lead to increased demand, the flexibility of food packaging machines makes it easier to increase or decrease production as needed. Unlike a traditional workforce, where demand peaks are difficult to cover, the highly flexible and versatile nature of food packaging machines means your production line can handle fluctuations in demand.

What Food Packing Machine Can Pack?

The food packing machine in Suntech can pack any type of food. In the fragile material, it can pack puffy food, chips, jelly, candy, pistachio nuts, nuts, apple slices, frozen dumplings, coffee beans, pasta, cotton candy, french fries, rice, pet food, small hardware, etc. The multihead weigher packing machine can pack all kinds of grain material, sheet material, strip material, and abnormity material such as biscuits, confect, camphor balls, currant, almond, chocolate, filbert, etc.

Multihead Weigher Packing Machine

Conclusion

All in all, to seize market share and get more customers, food companies need a reliable food packing machine to ensure a stable and clean food product supply. Good food packaging equipment can benefit the food business a lot.

Suntech is a food packing machine supplier, specializing in supplying advanced and precise food packing machines to many kinds of food businesses.