Product Description to Doypack Machine

It is suitable to use in packing the high accuracy and easy fragile material. Such as: puffy food,chips, jelly, candy, pistachio nuts, nuts, apple slices, frozen dumpling, coffee beans, pasta,cotton candy, french fries, rice, pet food, small hardwares, etc.

|

Model

|

SUN-D400C

|

|

Measuring Range

|

100-5000g

|

|

Packaging Speed

|

5-12bags/min

|

|

Bag Width

|

120-300mm

|

|

Bag Length

|

200-530mm

|

|

Bag Type

|

Stand-up bag, Zip doybag ,Pillow bag

|

|

Machine Weight

|

550kg

|

|

Power Supply

|

220V, 50Hz

|

|

Air Consumption

|

0.8Mpa, 0.8m³/min

|

Product Details to Doypack Machine

Our affordable, easy to use packaging machine are suitable for company wanting to automate their packaging processes for the first time or to the larger producer looking for more productivity and efficiency.

How to Delivery

We use non fumigation pallets plywood cases to pack machines.

Our Service

✔ Pre-Sale Service:

We will according your product feature, weight of each bag, and shape of bag make a quotation for you. Then more details we need communication such as material and thickness of film, dimension of bag you already have it or need we design for you, Operate language,what kind of voltage at the local.

✔ After-Sale Service:

Warranty: 1 Year except wearing parts ( Cutter, Belt, Horizontal and vertical Heating Tube etc), Most of components are free-replacement (PLC, Servo controller, Servo motor, Touch screen, Cylinder). Machine delivery will with a tool box, there have some parts are free.

Operation training:

1: Machine is very easy operate, delivery with manual, offer lots of photos and videos when machine in assembling or disassembling.

2: Welcome to our factory learning.

3: Engineers available to service machinery overseas.

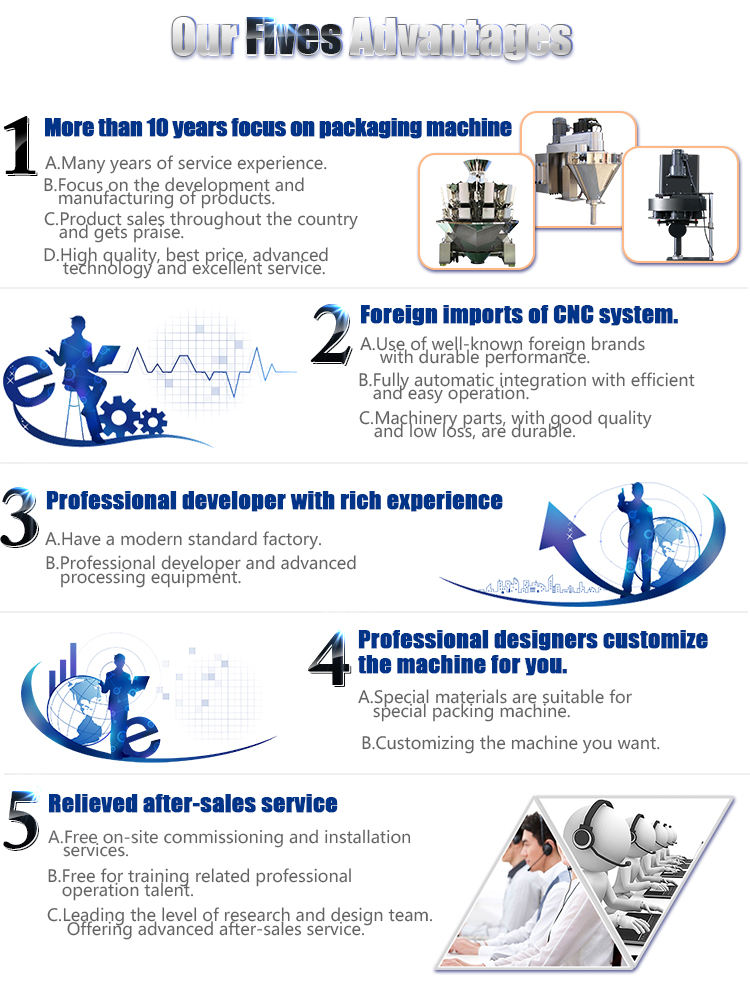

About Suntech

We has gained rich experience in the packing machinery field and has many mature technologies. So far, dozens of packaging machine series have been successfully developed to achieve the optimal matching of automatic weighing machines and packaging machines. It is widely used in Food, Beverage, Pharmaceutical ,Chemical, Hardware accessories and other industries. It is the preferred equipment to achieve production automation and improve production efficiency. At present, the products are exported to Europe, America, Middle East, Southeast Asia, Africa and other parts of the world, and are deeply trusted and praised by users.

We not only provide customers with high quality and reliable products, but also design and manufacture packaging equipment according to customers' actual requirements, provide packaging overall solutions, undertake various standard packaging machines OEM business, and provide professional technical service support for customers. To create greater value for customers.

"Strictly Abide by the Integrity, the Pursuit of Excellence", all the Suntech people must take it as their conviction and serve the customers wholeheartedly, warmly welcome customers at home and abroad to visit and guide, we hope to create brilliant success together with you!

Certifications

What is a Doypack Machine?

The doypack machine, also known as a stand-up pouch packaging machine, is a specialized device used in the packaging industry to create and fill Doypack pouches. A Doypack pouch is a flexible, stand-up pouch with an oval or rounded bottom and usually has a top seal or zipper for closure.

The doypack machine automates the process of forming these pouches from roll stock material, filling them with a product (such as powders, liquids, granules, or solid items), and sealing them to create a finished, ready-to-sell packaging solution. These machines often incorporate various features and technologies like precise filling systems, sealing mechanisms, and user-friendly interfaces to efficiently produce sealed pouches that are convenient for consumers to use and store.

What are the Features of the Doypack Machine?

The doypack machine is a testament to advanced engineering, delivering unparalleled efficiency and precision in packaging solutions. In this section, the author would give a brief introduction to the features of the doypack machine.

Advanced Design and Superior Functionality

Featuring a meticulously engineered design and impeccable craftsmanship, our machine offers seamless operation, simplified maintenance, and remarkable stability in adjustment, saving valuable time and reducing labor efforts significantly.

Precision and Reliability

Equipped with a servo film transporting system, this machine ensures precise positioning and synchronous membrane transport, guaranteeing stable and reliable packaging processes. The high-sensitivity fiber color tracking enhances accuracy in sealing positions, delivering consistently flawless results.

Intuitive Interface and Intelligent Control

With a high-precision color touch screen interface, parameter setting becomes a breeze, providing an intuitive platform for seamless operation. Its temperature-independent PID control system accommodates various material coatings, ensuring optimal performance across different materials.

Efficiency and Versatility

Featuring a self-diagnosis function that offers instant fault identification, this machine ensures continuous productivity. Additionally, the flexibility to adjust parameters during operation and the ability to mix different products at discharge enhance its versatility and efficiency.

Weigher Integration and Elevator Compatibility

When paired with our high-precision digital load cell weigher, integrated with a color touch screen for seamless interaction, this Doypack machine becomes a comprehensive solution. It's also compatible with our bucket elevator, ensuring automated feeding and stopping functions for a seamless packaging process.

Material and Build Quality

Constructed from top-grade SUS304 stainless steel or carbon steel, our machine ensures durability and suitability for a wide range of bulk materials, including snacks like potato chips and banana chips, various hardware items, and pharmaceutical products.

Multilingual Interface and Enhanced Security

Offering multilanguage support and different authority management, our machine caters to diverse operational needs, ensuring smooth functionality across various settings and user preferences.