What are the applications of Zipper Bag Packing Machine?

SUNTECH fully automatic rotary packaging machine with multi head weigher, it is suitable to use in packing all kinds of grain material, sheet material, strip material and abnormity material which such as candy, seeds, chips, nuts, nuts, dry fruit, jelly, biscuits, potato chips, pet food, grain, cereal, dilatant foodstuff, small hardware and plastic can be weighed by the ration.

According to customer needs,the machine can use stand up bag, gusset bag, zipper bag, pouch,three sides seal, four side seal etc. bag types.

.jpg)

Zipper Bag Packing Machine: Product Feature

1.Easy to operate,adopt advanced PLC from Germany Siemens, mate with touch screen and electric control system, the man-machine interface is friendly.

2.Frequency conversion adjusts the speed: this machine uses frequency conversion equipment, can be adjusted within the range according to the needs of reality in production.

3.Automatic checking: no pouch or pouch open error, no fill, no seal. the bag can be used again, avoid wasting packing materials and raw materials.

4.Safty device: Machine stop at abnormal air pressure, heater disconnection alarm.

5.Horizontal conveyor style to giving bag: it can put on more bags on the bag storage and have a low requirement about the quality of bags.

6.The width of the bags could be adjusted by electrical motor. Press the control-button could adjust the width of all clips, easily operate, and raw materials.

7.The packing materials loss low, what this machine is used the preformed bag, the bag pattern is perfect and has a high quality of the sealing part, this improved the product specification

Zipper Bag Packing Machine: Machine Specification

|

Model

|

SUN-S8-200

|

|

Working position

|

Eight-working position

|

|

Pouch material

|

Laminated film\PE\PP etc.

|

|

Pouch pattern

|

Flat pouch, 3 or 4 sealing bag, stand up bag, gusset bag etc.

|

|

Pouch size

|

W:100-200mm L:100-300mm

|

|

Speed

|

Up to 50 pouches/min(The speed depends on the product status and filling weight)

|

|

Weight

|

1250KGS

|

|

Voltage

|

380V 3phase 50HZ or customer customized

|

|

Total power

|

3.5KW

|

|

Compress air

|

0.4m3/min(supply by user)

|

|

Size

|

2200*1850*1500mm

|

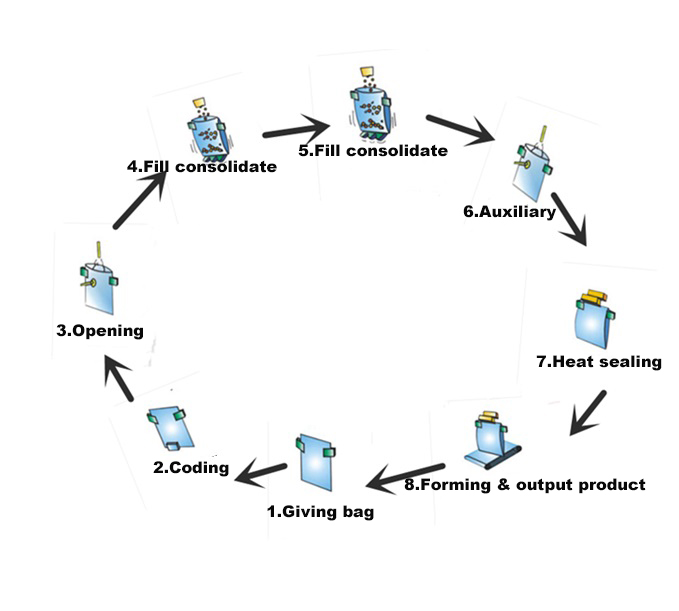

How Does the Zipper Bag Packing Machine Work?

Zipper Bag Packing Machine: Packaging & Shipping

- Packaging: machinery standard packaging or customized.

- Shipping: By Air, by Sea or by Express (DHL etc) Shipment cost will depend on the destination, shipment way and the weight of the goods.

>>Trade terms:

- Delivery Time: 20-30 Days.

- Please tell us quote EXW,FOB,or CIF price? Which port is very impotant.

- Payment: T/T, 30% deposits, 70% balance before deliverying. L/C acceptable.

Kindly reminder:

Please let us know the follow packing details when you offer,so that we can check if this model is suitable for your case.Thank you in advance.

1. Product details & weight

2. Bag width,bag length

3. Bag shape

4. Packing film/ pouch material

What is a Zipper Bag Packing Machine?

A zipper bag packing machine is a type of packaging machine specifically designed to fill and seal zipper bags or resealable bags. The zipper bag packing machine mainly consists of several procedures, includings conveying bag, coding, opening bag, fill consolidate, fill the consolidate again, auxilary, heat sealing, and forming and output product.

What are the Advantages of Investing Zipper Bag Packing Machine?

As a manufacturer and supplier of zipper packing machines, we have launched a series of zipper bag packing machines to satisfy various production needs. In this section, we will show you why our machines are excellent.

●User-Friendly Operation

Our machine is equipped with an advanced PLC from Germany Siemens, along with a touch screen and electric control system, making the man-machine interface exceptionally user-friendly. With easy-to-follow instructions, anyone can efficiently operate the machine.

●Adjustable Speed

To cater to the demands of real-time production, our machine incorporates frequency conversion equipment. This allows you to adjust the speed within a wide range, ensuring optimal production efficiency.

●Automatic Checking

Say goodbye to packaging errors! The machine automatically detects and prevents pouch open errors, no-fill situations, and sealing issues. This feature not only saves packaging materials but also reduces raw material wastage, maximizing your production output.

●Safety First

Our machine is designed with safety in mind. It includes a safety device that halts the operation in case of abnormal air pressure or heater disconnection, keeping your production process secure.

●Flexible Bag Options

Whether you need stand-up bags, gusset bags, zipper bags, pouches, three-sides seal, or four-sides seal bags, this machine can handle it all. Adapt it to your specific packaging requirements with ease.

●Bag Width Adjustment

The width of the bags is easily adjustable using the electrical motor and control button. This feature allows you to customize the bags to accommodate various product sizes efficiently.

●Reduced Packaging Material Loss

Our machine uses preformed bags with perfect bag patterns and superior sealing quality, resulting in minimal packaging material loss and improved product specifications.

What are the Applications of Zipper Bag?

A zipper bag is one of the most popular packaging optin in many applications. In this section, the author list some of the main applications.

●Food Storage: Zipper bags are commonly used to store various types of food items such as snacks, fruits, vegetables, sandwiches, and leftovers. The resealable feature helps maintain freshness and prevents spills or leakage.

●Travel Toiletries: They are handy for organizing and carrying travel-sized toiletries like shampoo, conditioner, lotion, and other personal care products while traveling.

●Document Protection: Important documents like passports, tickets, or certificates can be kept safe and protected from moisture and dirt in a sealed zipper bag.

●Jewelry and Accessories: Delicate jewelry pieces, watches, and accessories can be stored safely in individual zipper bags to prevent tangling and damage.