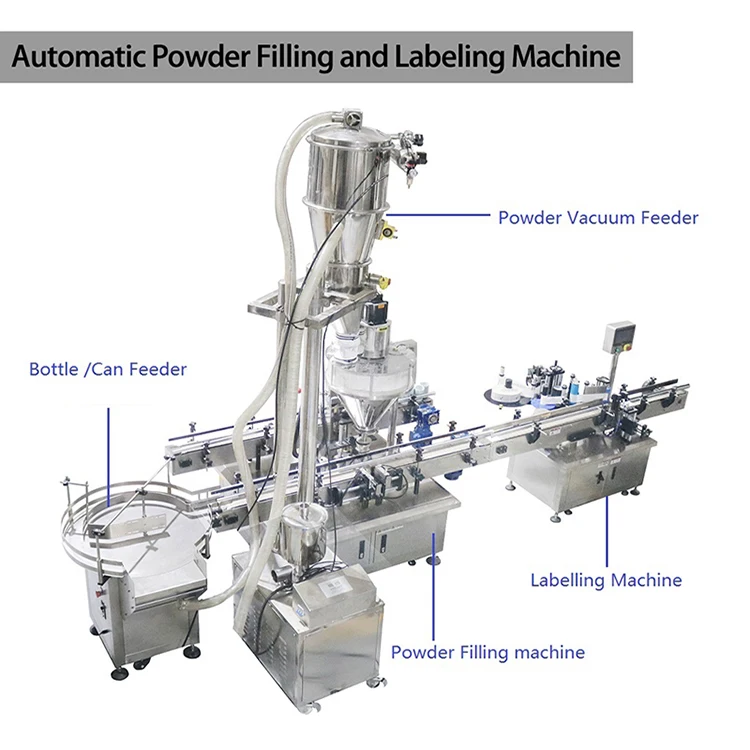

Advanced Protein Powder Packing Machine with Auto Packing Solution for Precise, Efficient Packaging

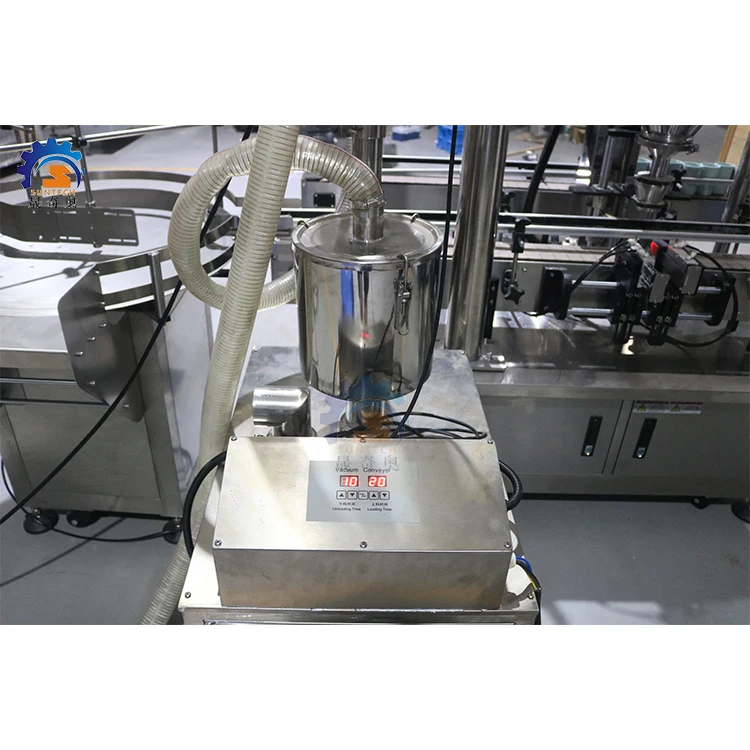

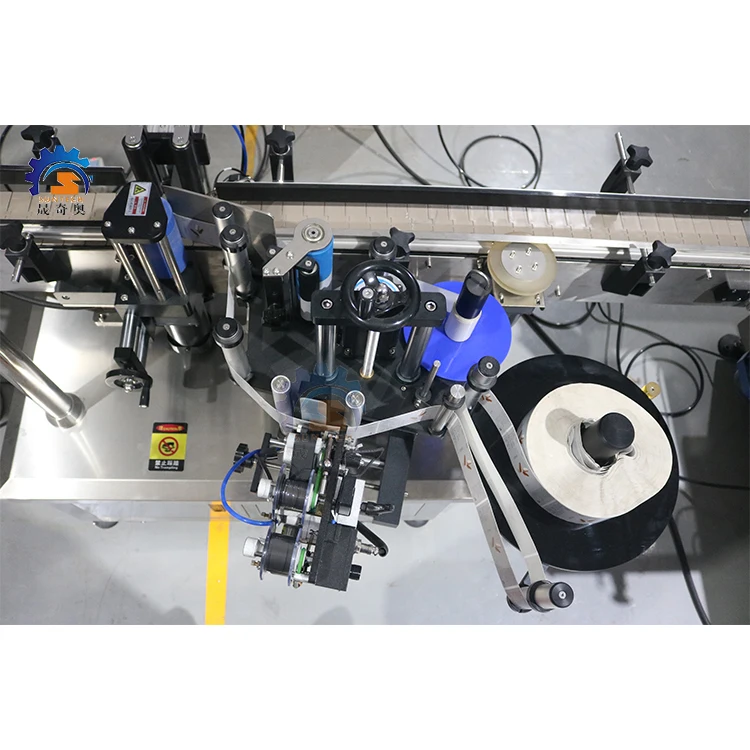

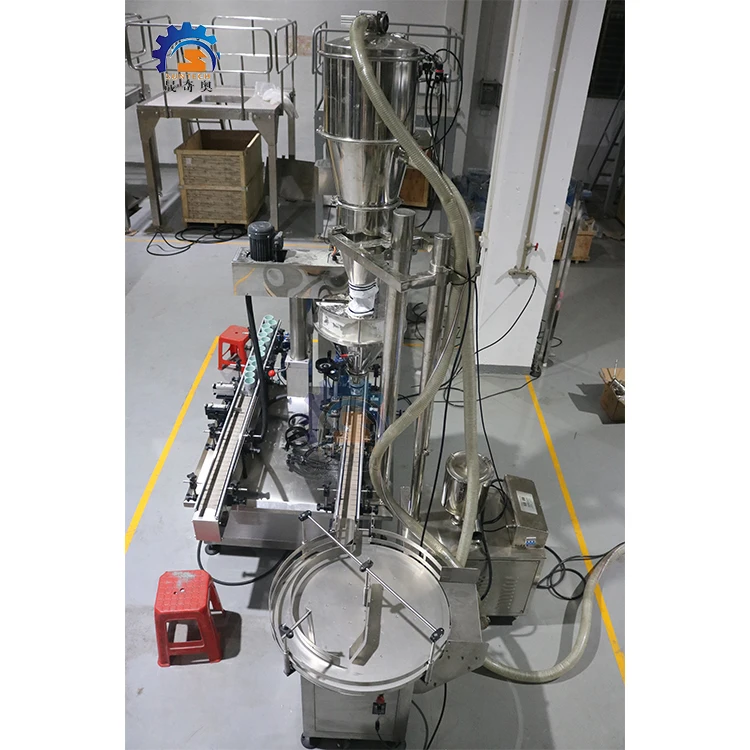

The advanced protein powder packing machine offers a state-of-the-art auto packing machine solution that ensures precise and efficient packaging. Designed for high-volume production environments, this machine guarantees consistent accuracy, reducing the risk of errors and minimizing product waste. It is equipped with cutting-edge technology that helps maintain the integrity of the protein powder, ensuring that every package is sealed properly, preserving freshness and quality.

This system is not only fast but also reliable, optimizing production speed without compromising on the quality of the product. Whether it's whey protein, casein, or plant-based protein powder, the machine adapts to various formulations and packaging needs, offering flexibility for different product lines. The automated process reduces the need for manual labor, increasing efficiency and lowering operational costs.

With its high-speed capabilities and precision controls, the protein powder packing machine is perfect for businesses that require both speed and accuracy in their packaging operations. The system also features advanced sensors and monitoring tools that help detect and correct any issues in real-time, ensuring smooth and uninterrupted production runs. This makes it ideal for maintaining high production standards in the nutritional supplement industry, where quality and efficiency are paramount.

Additionally, the protein powder packing machine is designed to meet industry standards for safety and hygiene, making it a great investment for businesses looking to enhance their production lines while keeping their products safe and well-packaged.

Product Description

In the food and medicine industries, this protein powder packing machine can efficiently handle various powder products such as flour, maize flour, coffee powder, milk powder, cocoa powder, custard powder, chili powder, seasoning powders, and more. Whether it's for packaging essential ingredients in the food sector or for medicinal powders in the pharmaceutical industry, this machine ensures precision and consistency, maintaining product integrity while providing high-speed packing solutions. Its adaptability makes it perfect for handling powders that require precise dosing and hygienic conditions, ensuring that the end product meets the highest quality standards.

Additionally, the machine is highly effective in the chemical coatings industry, where it is used to package putty powder, dry mortar powder, detergent powder, and other similar products. In these industries, the need for durable, efficient, and precise packaging solutions is paramount. This protein powder packing machine is equipped to handle even the most challenging powders, offering a dust-free, clean environment and ensuring that each package is filled accurately. Whether it’s for delicate food ingredients or heavy-duty chemical powders, the machine adapts to various powder types and packaging requirements, offering unparalleled flexibility and efficiency.

The versatility of this protein powder packing machine extends beyond food, medicine, and chemicals, making it an excellent choice for businesses across a range of industries. With the ability to accommodate different types of powders, the machine helps streamline production processes, enhance operational efficiency, and maintain high levels of hygiene and quality control throughout the packing process.

|

Model

|

SUN-S350

|

|

Bottle Diameter

|

Φ30mm-Φ135mm(customizable)

|

|

Bottle Height

|

40mm-200mm(customizable)

|

|

Speed

|

10-30 bottles/min

|

|

Power Supply

|

220V/50HZ

|

|

Control system

|

PLC

|

|

Air Consumption

|

0.1m³/min

|

|

Dimension

|

2000mm*700mm*1200mm(L*W*H)

|

|

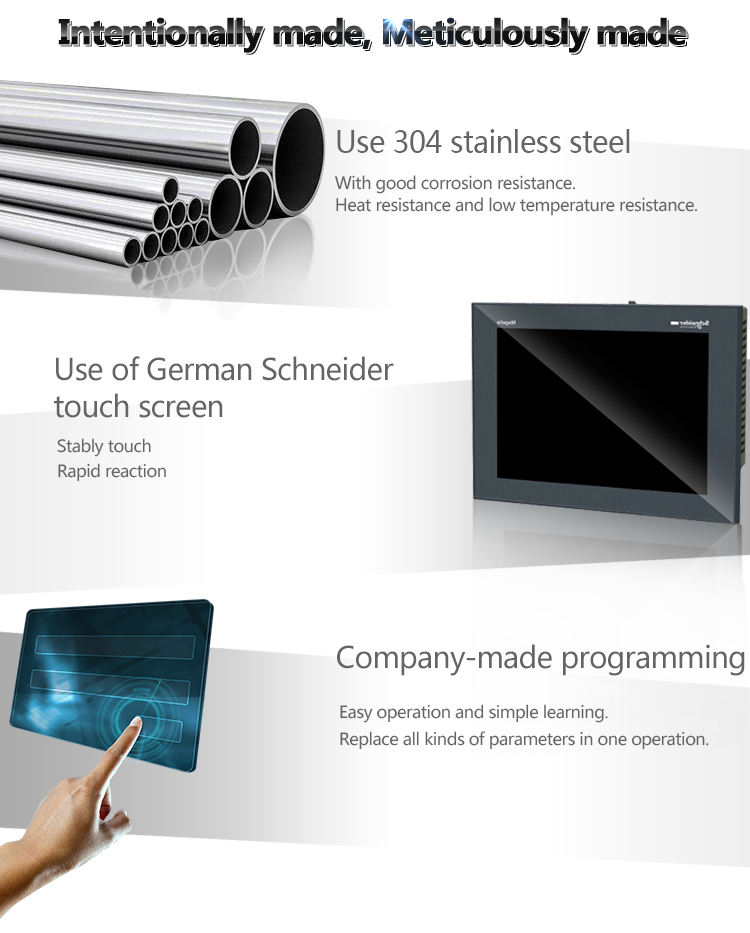

Equipment Material

|

304

|

|

Weight

|

150kg

|

Our affordable, easy-to-use Protein Powder Packing Machine are the ideal solution for companies looking to automate their packaging processes, whether it’s the first time implementing automation or for larger producers aiming to boost productivity and efficiency.

For companies new to automation, our Protein Powder Packing Machine provides a user-friendly, cost-effective entry point into automated packaging. Designed with simplicity in mind, the machine offers easy setup and operation, allowing businesses to quickly transition from manual to automated packaging without extensive training or a steep learning curve. This makes it an excellent choice for small to medium-sized enterprises or startups that want to streamline their production without incurring heavy initial costs. With intuitive controls and a straightforward interface, even operators with minimal technical experience can achieve consistent, high-quality results.

For larger producers or companies with established production lines, our Protein Powder Packing Machine offers a powerful solution to increase productivity and efficiency. With advanced features like high-speed filling, automated adjustment of packaging parameters, and the ability to handle multiple formulas, this machine can easily scale to meet the demands of larger operations. It reduces downtime, enhances throughput, and allows businesses to meet tight production deadlines while maintaining product quality. The machine’s versatility also ensures that it can handle a wide range of powdered goods, from protein powders to other types of powders, making it a long-term investment for growing companies seeking to optimize their packaging processes.

No matter the size of your operation, our Protein Powder Packing Machine is engineered to deliver reliable performance, reduce labor costs, and ensure high-quality packaging. Whether you’re just beginning to automate or looking to further enhance the efficiency of your existing production line, our Protein Powder Packing Machine provides an affordable and scalable solution to meet your needs.

How to Delivery

We use non fumigation pallets plywood cases to pack machines.

Our Service

✔ Pre-Sale Service of Protein Powder Packing Machine:

We will according your product feature, weight of each bag, and shape of bag make a quotation for you. Then more details we need communication such as material and thickness of film, dimension of bag you already have it or need we design for you, Operate language,what kind of voltage at the local.

✔ After-Sale Service:

Warranty: 2 Years except wearing parts ( Cutter, Belt, Horizontal and vertical Heating Tube etc), Most of components are free-replacement (PLC, Servo controller, Servo motor, Touch screen, Cylinder). Machine delivery will with a tool box, there have some parts are free.

Operation training:

1: Machine is very easy operate, delivery with manual, offer lots of photos and videos when machine in assembling or disassembling.

2: Welcome to our factory learning.

3: Engineers available to service machinery overseas.

About Suntech

We have gained rich experience in the Protein Powder Packing Machine field and have developed many mature technologies. So far, dozens of Protein Powder Packing Machine series have been successfully developed to achieve the optimal integration of automatic weighing machines and packaging machines. These machines are widely used in the food, beverage, pharmaceutical, chemical, hardware accessories, and other industries. They are the preferred equipment to achieve production automation and improve overall production efficiency. Currently, our Protein Powder Packing Machines are exported to Europe, America, the Middle East, Southeast Asia, Africa, and other parts of the world, gaining deep trust and praise from users globally.

We not only provide customers with high-quality and reliable Protein Powder Packing Machines, but also design and manufacture packaging equipment tailored to customers' specific requirements. We offer comprehensive packaging solutions, undertake various standard packaging machine OEM businesses, and provide professional technical support for our customers. Our goal is to create greater value for our clients.

"Strictly abide by integrity, the pursuit of excellence" – this philosophy is the core belief of everyone at Suntech. We are committed to serving our customers wholeheartedly and warmly welcome customers from both domestic and international markets to visit and guide us. Together, we look forward to achieving brilliant success with you!

Certifications

FAQ of Protein Powder Packing Machine

1. What types of protein powders can be packaged using a Protein Powder Packing Machine?

Our Protein Powder Packing Machine is designed to handle a variety of protein powders, including whey protein, casein, plant-based proteins (such as soy, pea, or rice protein), and other nutritional powders. The machine is adaptable and can be customized to handle different formulations, ensuring precise packaging for a wide range of products. Whether your protein powder is fine, coarse, or has added ingredients, this machine can efficiently package it with high accuracy and minimal wastage.

2. How does the Protein Powder Packing Machine ensure the quality and hygiene of the packaged products?

The Protein Powder Packing Machine is built with food-grade stainless steel and other materials that meet stringent hygiene standards. The machine is designed to minimize exposure to contaminants and prevent cross-contamination during the packaging process. It also features dust removal systems and sealed packaging compartments to prevent the powder from spilling or contaminating the production area. For additional safety, the machine incorporates regular cleaning and maintenance procedures to ensure that the packing process remains hygienic and compliant with industry standards.

3. Can the Protein Powder Packing Machine be customized for different packaging formats and sizes?

Yes, the Protein Powder Packing Machine can be customized to accommodate various packaging formats, including pouches, bags, bottles, and canisters. It offers flexibility in terms of filling capacities and packaging sizes, ranging from small single-serving packages to larger bulk containers. The machine allows for quick and easy adjustments to suit different production requirements, making it ideal for businesses with multiple product lines or fluctuating packaging needs. Additionally, it can store different formulas and production parameters for easy switching between packaging types.