What are the Applications of A Premade Pouch Packing Machine?

01. Product application:

SUNTECH powder premade bag packing machine is widely used in food factory, chemical factory, suitable for packing all kinds of powder product, such as, rice flour, coffee powder, sulfur powder, milk powder, seasoning powder.

According to customer needs,the machine can use stand up bag, gusset bag, zipper bag, pouch,three sides seal, four side seal etc. bag types.

Product Description to A Premade Pouch Packing Machine

Product feature:

1.Easy to operate,adopt advanced PLC from Germany Siemens, mate with touch screen and electric control system, the man-machine interface is friendly.

2.Frequency conversion adjusts the speed: this machine uses frequency conversion equipment, can be adjusted within the range according to the needs of reality in production.

3.Automatic checking: no pouch or pouch open error, no fill, no seal. the bag can be used again, avoid wasting packing materials and raw materials.

4.Safty device: Machine stop at abnormal air pressure, heater disconnection alarm.

5.Horizontal conveyor style to giving bag: it can put on more bags on the bag storage and have a low requirement about the quality of bags.

6.The width of the bags could be adjusted by electrical motor. Press the control-button could adjust the width of all clips, easily operate, and raw materials.

7.The packing materials loss low, what this machine is used the preformed bag, the bag pattern is perfect and has a high quality of the sealing part, this improved the product specification

Machine Specification: A Premade Pouch Packing Machine

|

Model

|

SUN-S8-200

|

|

Working position

|

Eight-working position

|

|

Pouch material

|

Laminated film\PE\PP etc.

|

|

Pouch pattern

|

Flat pouch, 3 or 4 sealing bag, stand up bag, gusset bag etc.

|

|

Pouch size

|

W:100-200mm L:100-300mm

|

|

Speed

|

Up to 50 pouches/min(The speed depends on the product status and filling weight)

|

|

Weight

|

1250KGS

|

|

Voltage

|

380V 3phase 50HZ or customer customized

|

|

Total power

|

3.5KW

|

|

Compress air

|

0.4m3/min(supply by user)

|

|

Size

|

2200*1850*1500mm

|

Machine details of A Premade Pouch Packing Machine

Working Processing: A Premade Pouch Packing Machine

Packaging & Shipping: A Premade Pouch Packing Machine

- Packaging: machinery standard packaging or customized.

- Shipping: By Air, by Sea or by Express (DHL etc) Shipment cost will depend on the destination, shipment way and the weight of the goods.

Trade terms:

- Delivery Time: 10-20 Days.

- Please tell us quote EXW,FOB,or CIF price? Which port is very impotant.

- Payment: T/T, Western Union, MoneyGram,PayPal; 30% deposits; 70% balance before deliverying. L/C acceptable.

Company Information

We has gained rich experience in the packing machinery field and has many mature technologies. So far, dozens of packaging machine series have been successfully developed to achieve the optimal matching of automatic weighing machines and packaging machines. It is widely used in Food, Beverage, Pharmaceutical ,Chemical, Hardware accessories and other industries. It is the preferred equipment to achieve production automation and improve production efficiency. At present, the products are exported to Europe, America, Middle East, Southeast Asia, Africa and other parts of the world, and are deeply trusted and praised by users.

We not only provide customers with high quality and reliable products, but also design and manufacture packaging equipment according to their actual requirements, provide packaging overall solutions, undertake various standard packaging machine OEM business, and provide professional technical service support for customers. To create greater value for customers.

"Strictly Abide by the Integrity, the Pursuit of Excellence", all the Suntech people must take it as their conviction and serve the customers wholeheartedly, warmly welcome customers at home and abroad to visit and guide, we hope to create brilliant success together with you.

| Kindly reminder |

| Please let us know the follow packing details when you offer,so that we can check if this model is suitable for your case.Thank you in advance. |

| 1. Product details & weight |

|

| 2. Bag width,bag length |

|

| 3. Bag shape |

|

| 4. Packing film/ pouch material |

|

What is A Premade Pouch Packing Machine?

Different from other packing machines, a premade pouch packing machine uses preformed bags to pack the items to ensure low packing material loss.

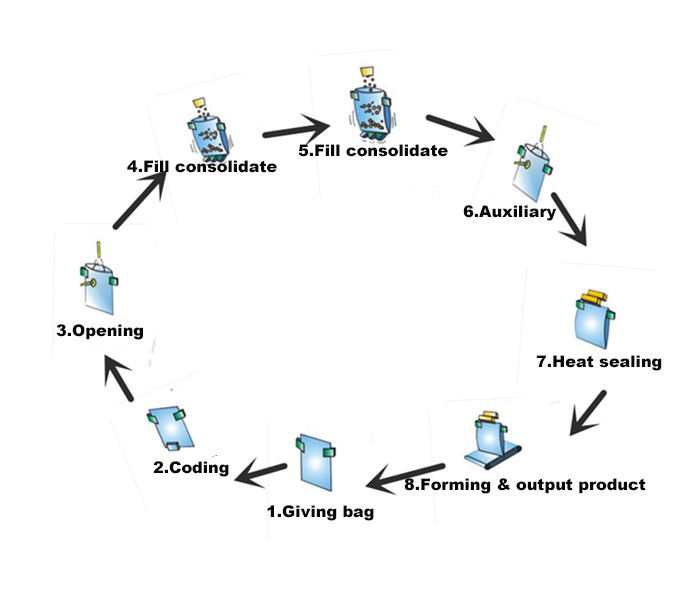

How Does A Premade Pouch Packing Machine Work?

The whole working process of the premade pouch packing machine can be divided into 7 steps.

Step 1: Bag Giving

The process starts with the machine receiving premade pouches or bags from a supply source. These bags are typically flat and ready for filling.

Step 2: Coding

Before filling, the bags might undergo coding where essential information such as expiry dates, batch numbers, or product information is printed or labeled onto the pouches for identification and tracking purposes.

Step 3: Opening

The premade bags are then opened, usually by mechanical arms or a suction mechanism, to prepare them for the filling process.

Step 4: Fill Consolidate

Once the bags are opened, the product to be packaged is filled into them. This can be done through various methods depending on the product—auger filling for powders, liquid filling for liquids, or even a combination for mixed products. After filling, the contents might be consolidated or settled to ensure proper quantity and reduce air pockets.

Step 5: Auxiliary Functions

Some machines might have additional functions like adding desiccants, oxygen absorbers, or inserting special promotional materials before sealing the bags. This step can be customizable based on the specific packaging requirements.

Step 6: Heat Sealing

The open end of the pouches is sealed shut to enclose the product securely. Heat sealing is a common method where heat is applied to the bag to melt the material, sealing it effectively. Different sealing techniques might be used based on the bag material—such as impulse sealing for thin materials or continuous sealing for thicker ones.

Step 7: Forming & Output

The Premade Pouch Fill And Seal Machine might also shape or form the pouches into their final desired form, such as creating a stand-up pouch, before they are discharged from the machine. The finished, sealed pouches are then ready for packaging into boxes or shipping for distribution.

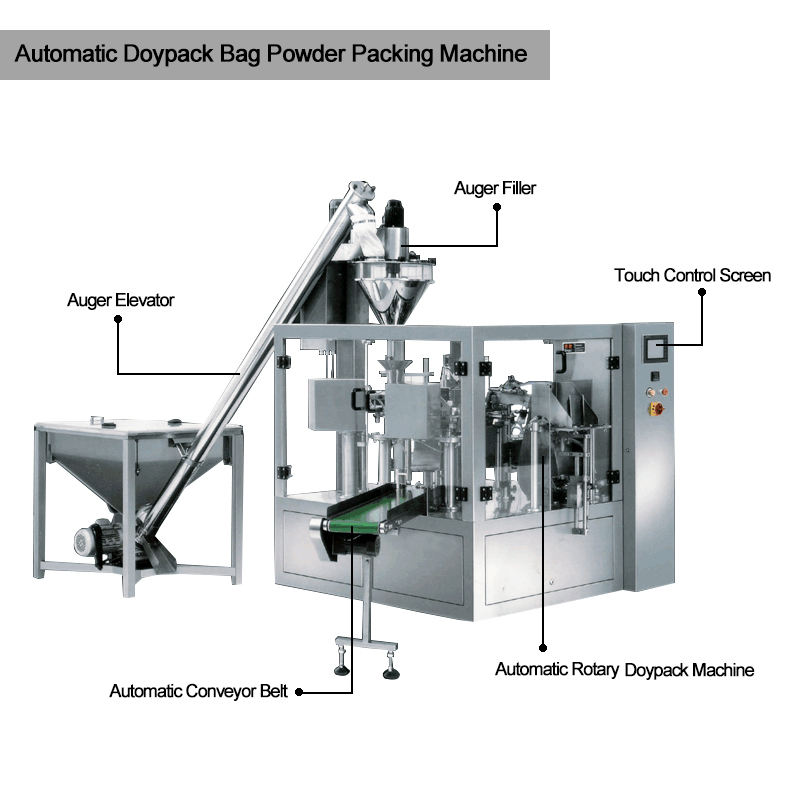

What are the Main Parts of Premade Pouch Packing Machine?

In this section, the details of the components of the zipper pouch packing machine is presented.

Name: Doypack main packing machine

*Imported PLC operation interface is adopted, and the whole process is automatically controlled, and the operation is convenient.

*Automatic detection function, if the bag is not opened or the bag is incomplete, no feed or heat

Sealing and bags can be reused. and waste can be avoided,saving production costs for users.

*Packing bags are suitable for a wide range, such as three-dimensional bags, flat bags, handbags, zippers

Bags, four-side-sealed bags, three-side-sealed bags, paper bags and other composite bag films Bag making.

*Quickly change the size of the packaging bag, the width of the automatic bag feeding device can be adjusted by hand

Easy and quick adjustment of the handle

*This machine uses frequency conversion speed regulation device,the packaging weight can be adjusted at any time, and the operation is convenient.

Name: Auger Filler

*This machine is made of stainless steel, hydraulic lifting, especially for GMP certification.

*Using a unique mechanical transmission that makes the structure very simple, stability is good and overload capacity is strong.

*Filling, which adopts servo electric drive screw with accurate position,high precision, fast speed, big torque, long life, good stability.

Name: Powder feeder

*This Doypack Packing Machine adopt screw conveying material, the storage can be vibrated. It is suitable for conveying various powder and little pellets.